Plastic moulding shop

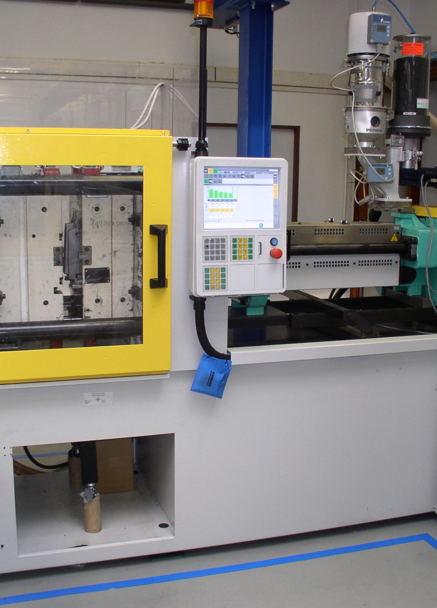

We are a modern plastic moulding plant, producing quality parts for the automotive, medical, electrical, consumer goods and food industries. You will find 1K and 2K injection molding, pad printing, sub-assembly assembly, injection molding with metal inlays and much more.

About the moulding shop

Plastic injection moulding

The plastic moulding plant was established within the company Chotěbořské strojírny a.s. in September 2010.

The operation was initially equipped with four machines from Arburg with a clamping force of 40 to 150t. In 2011, the Zhafir all-electric machine with a clamping force of 90t was added to the machine portfolio. In 2012, another machine was purchased from Engel with a clamping force of 220t. In 2015, the company invested considerable funds in further development operation of the pressing plant. A new hall with a bridge crane with a capacity of 12.5t was built and additional machines and peripherals. In particular, presses from Engel with a clamping force of 50, 120, 300 and 600t were purchased. Following this extension, the necessary peripherals were also added.

For the production of 2K parts we use an Engel machine with a clamping force of 350 t and a Viper 20 robot. The current technical equipment includes 17 injection moulding machines, 1K and 2K, with clamping forces from 40 to 600 tonnes.

The maximum injection volume is 2,480 cm3.

We supply parts for the automotive, medical, electrical, construction and food industries. Maintenance and repairs of tools are provided by our own resources with the support of the Tool Shop.

Tampoprint

With the development of our press shop we responded to customer requirements and retrofitted our press shop with two printing machines on which we print plastic parts mainly for medical devices. In the production of products, the precision and repeatability of printing are taken into account, especially for multi-colour printing.

Additional operations

In addition to the production of plastic parts, we offer subassembly and 3D printing of prototype samples.

Processed materials

Commonly processed materials in our moulding plant: PA 66, ABS, PP, PA 6, PC, PA 66 + PA 6, TPE, ASA, ABS/PC, POM, PE, HDPE, PS. We process materials either fully coloured or painted, which we finish to a shade according to the customer's requirement - we have fully equipped dyeing machines with control system and connection to the control press units.

REFERENCES

We go the extra mile for our customers. Customers and our employees are the most valuable asset we have.

VIEW REFERENCESContact moulding plant

MOULDING SHOP MANAGER

Miloslav Dalecký

tel.: +420 569 551 275

phone: +420 725 601 624

email: plasty@chss.cz

Chotěbořské strojírny, a.s.

RN: 45534519 / VAT number: CZ45534519

Address: Herrmannova 520, 583 01 Chotěboř / map

Tel: +420 569 551 111

View all contact details